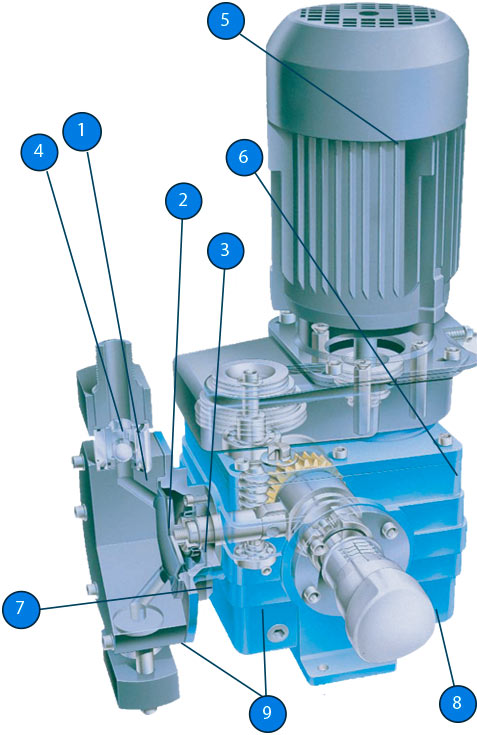

The Encore 700 (Formally the Wallace and Tiernan Series 44) is a rugged, heavy-duty mechanical diaphragm metering pump available with six diaphragm sizes and double simplex capability to handle capacities up to 660 gallons per hour and backpressure to 175 psi.

- Non-Loss motion stroke adjusts mechanism for reliability and longevity.

- Available in either a direct drive configuration or a pulley coupled arrangement for additional 4:1 turndown on stroke frequency.

- Manual control or control via an automatic stroke length positioner or variable speed drive or both.

- Optional diaphragm leak detector.

UGSI Has Taken the Superior Wallace and Tiernan Series 44 and IMPROVED IT with a More Rugged Drive Mechanism and A Composite Diaphragm for Longer Life and Easy Serviceability.

- Short suction and discharge ports minimize friction losses and cavitation, improving hydraulic characteristics.

- The composite diaphragm is manufactured to stringent specifications to ensure long life. The design incorporates PTFE facing, for the highest degree of chemical resistance.

- This double diaphragm isolating design eliminates the risk of cross-contaminating gearbox lubricant and process fluid.

- The proven design includes wide flow paths and four-point guides to control ball rise and assure proper seating. The valve housing is compression-sealed to the pump head and pipe connectors by O-rings and is easily removed for the service or replacement without disturbing the external piping.

- Available with standard induction, variable speed, or inverter duty motors for wider operating ranges and automatic process control.

- This proven (Wallace and Tiernan 44 Series design) provides robust mechanical assembly features and liberal use of heavy-duty parts.

- An optional diaphragm leak detection system senses the early stages of diaphragm failure.

- Obtain precise and highly repeatable feed rate settings with a 10-turn, micrometer-type stroke length adjuster. A percent scale and vernier indicate stroke length in 0.25% increments.

- Proven, reliable drive and control mechanism with precision liquid end design offer superior metering and process control performance.

Dry Chemical Feed Equipment & Control

UGSI Chemical Feed Series 32-050 and 32-055 Volumetric Screw Feeders are designed to feed a wide range of water and wastewater treatment chemicals as well as industrial process chemicals and dry materials. Utilizing 4 different feed screw sizes, capacities from 0.03 to 50 cubic feet are available. The continuous operating range is 20:1, extendable to 60:1 by belt position on a stepped pulley.

Series 32-050 Feeder – This economical feeder features a constant speed feed screw that is controlled by a manually-set percent timer. The feeder cycles on and off over a 1-minute feed cycle depending on the timer setting.

Series 32-055 Feeder – This highly adaptable feeder features a variable speed feed screw with 3 different control arrangements: Manual control via a feeder mounted potentiometer; Start-stop control from a remote interlock; mA control from a flow signal or remote plant control.

Features and Benefits:

- Rugged, corrosion-resistant construction for long service life

- Design simplicity for reliable operation with minimal maintenance

- Various control options-manual to fully automatic

- Accuracy of 1% to 2% f.s. with free-flowing materials

- Wide operating range

- Integral hopper agitation for difficult-to-handle materials

- Special arrangements for carbon and potassium permanganate

- Hazardous location arrangement (FM approved)

- Food-grade arrangement available for industrial applications

Feeders Below are Available with a Complete Range of Configurations and Accessories:

- Solution tanks from 25 to 500 gal. capacity

- Wetting cones

- Feeder stands

- Extension hoppers

- Charging hoppers

- Bag loading hoppers

- Dust collectors

- Shut-off gates

- Hopper level switches

- Tank feed systems

We offer a variety of technologies for feeding and metering dry chemicals commonly used in the treatment of municipal and industrial water and wastewater.

Our extensive line of the volumetric screw and belt-type volumetric and gravimetric feeders, feeder tank systems, lime-slaking systems and accessories can handle the most commonly used chemicals in the municipal water applications such as calcium oxide, calcium hydroxide, ferric sulfate, soda ash, potassium permanganate, aluminum sulfate, and carbon. Chemicals used in industrial processes include bleach, clay gypsum plastic pellets, pigments, and flour.

-

-

- Neutralization: Sludge control

- PH Control: Softening

- Coagulation: S02

- Sedimentation: Odor control

- Fluoridation: Dry ingredients

-

For more product detail

call Stephen Bucci at (610) 497-5900